3D printing technology is mainly used by consumer electronic industry. 3D Printing technology has started switching manufacturing industry in new dimension. The manufacturing industry could design complex components, with the help of 3D printing. The manufacturers are able to improve their supply chains, light-weight product components and design minute, with the help of the 3D technology.

3D Printing Market in Aerospace and Consumer Electronics market is expected to grow at a CAGR of 26% during the forecast period 2017–2023. The report consumes 3D printing market in aerospace and consumer electronics market in terms of trends, regions and vendor assessments on the basis of technology, R&D spending, and product offerings.

The popular 3D printing materials are rubber, plastic, wax, ceramics and metals. Metals are said to be one of the fastest growing 3D printing materials, whereas plastic is currently dominating the global 3D printing materials market. Metal alloys are more preferred by the aerospace industry whereas plastics and wax are being preferred by the consumer electronics. Americas and Europe are currently dominating the market. It is expected that in the near future, Asia Pacific will be the key 3D printing regions. Singapore, India, and Japan will also be the key countries in the region. Rising Public Private Partnerships (PPPs), less raw material costs and increased investments in R&D in developing countries are helping the 3D printing market in aerospace and consumer electronics markets.

The major players included in this report are 3D Systems, Aerojet Rocket Dyne, Airbus, Boeing, GE Aviation, HP Development Company, Rolls-Royce, and Airbus.

This report offers major trends, industry trends which is going to play a major role in 3D printing market during the forecasted year. Moreover, this report can also tailored as per the requirement by the users, and also available with deeper segmentation by regions, countries, verticals, and vendor profiling.

1. Introduction

1.1. Goal & Objective

1.2. Report Coverage

1.3. Supply Side Data Modelling & Methodology

1.4. Demand Side Data Modelling & Methodology

2. Executive Summary

3. Market Outlook

3.1. Introduction

3.2. Current & Future Outlook

3.3. DROC

3.3.1. Drivers

3.3.2. Restraints

3.3.3. Opportunities

3.3.4. Challenges

3.4. Market Entry Matrix

3.5. Market Opportunity Analysis

3.6. Market Regulations

3.7. Pricing Mix

3.8. Key Customers

3.9. Value Chain & Ecosystem

4. 3D Printing in Aerospace & Consumer Electronics Market Analysis, By Industry

4.1. Aircrafts

4.2. Spacecraft’s

4.3. UAV’s

4.4. Others

5. 3D Printing in Aerospace & Consumer Electronics Market Analysis, By Region

5.1. North America

5.1.1. U.S.A

5.1.2. Canada

5.1.3. Mexico

5.2. Asia-Pacific

5.2.1. India

5.2.2. Japan

5.2.3. China

5.2.4. South Korea

5.2.5. Australia

5.2.6. Others

5.3. Europe

5.3.1. Germany

5.3.2. UK

5.3.3. Sweden

5.3.4. France

5.3.5. Italy

5.3.6. Others

5.4. Middle East & Africa

5.4.1. Saudi Arabia

5.4.2. UAE

5.4.3. Others

5.5. South America

5.5.1. Brazil

5.5.2. Others

6. Supply Market Analysis

6.1. Strategic Benchmarking

6.2. Market Share Analysis

6.3. Key Players

6.3.1. Ceno Technologies

6.3.2. Aerojet Rocket Dyne

6.3.3. Airbus, Boeing

6.3.4. GE Aviation

6.3.5. HP Development Company

6.3.6. Rolls-Royce

6.3.7. Airbus & Others

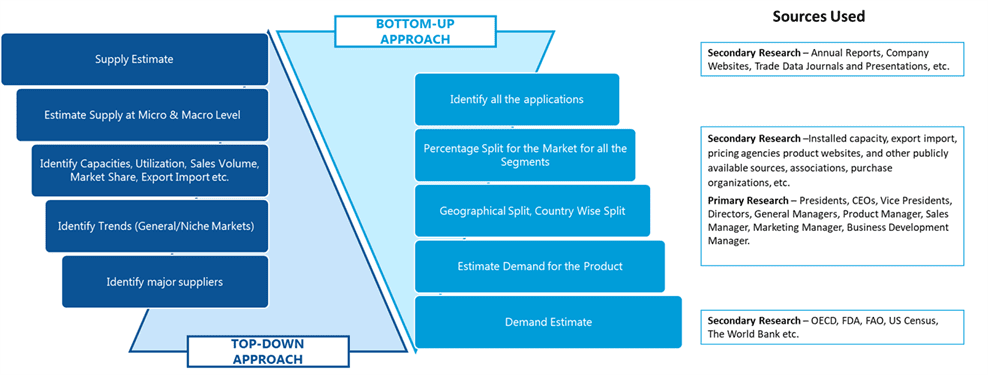

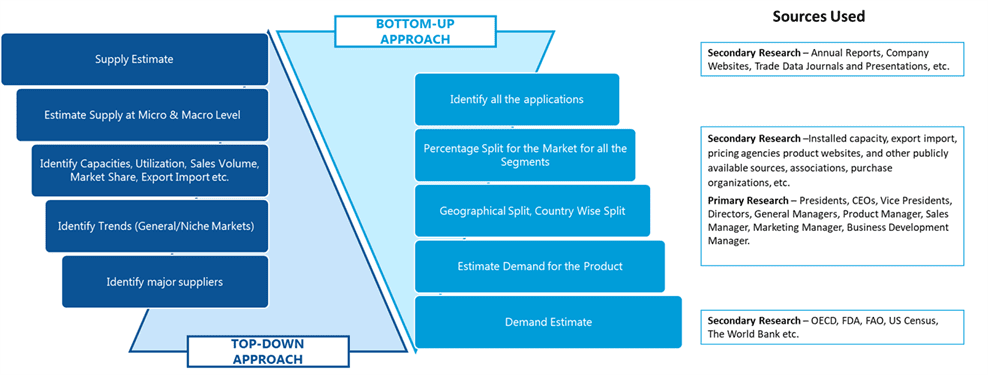

SDMR employs a three way data triangulation approach to arrive at market estimates. We use primary research, secondary research and data triangulation by top down and bottom up approach

Secondary Research:

Our research methodology involves in-depth desk research using various secondary sources. Data is gathered from association/government publications/databases, company websites, press releases, annual reports/presentations/sec filings, technical papers, journals, research papers, magazines, conferences, tradeshows, and blogs.

Key Data Points through secondary research-

Macro-economic data points

Import Export data

Identification of major market trends across various applications

Primary understanding of the industry for both the regions

Competitors analysis for the production capacities, key production sites, competitive landscape

Key customers

Production Capacity

Pricing Scenario

Cost Margin Analysis

Key Data Points through primary research-

Major factors driving the market and its end application markets

Comparative analysis and customer analysis

Regional presence

Collaborations or tie-ups

Annual Production, and sales

Profit Margins

Average Selling Price

Data Triangulation:

Data triangulation is done using top down and bottom approaches. However, to develop accurate market sizing estimations, both the methodologies are used to accurately arrive at the market size. Insert Image