The research of thickening & gelling agents used in Cosmetics market mainly focuses on North America, Europe, Asia (excluding and China) and China covering:

Market participants of thickening & gelling agents used in Cosmetics:

Producers (active, potential producers)

End users

Raw material suppliers

Major traders

Market analysis

Capacity

Production

Consumption trends and forecast

Value chain analysis

Price analysis

Regions / countries

North America

Western Europe

Asia pacific excluding China

China

How this report will add value to your organisation

This report provides the in-depth analysis of the complete value chain from the raw material suppliers to the end users. We have critically analysed following parameters and their impact in the industry:

1. Improvement in top line and bottom line growth

Analysis trend & forecasts by end use markets will help you to understand how the growth in consumption is expected in next 5 years and what will be the key factors that will support the growth. This will help to make a clear plan for the top line growth. Price analytics will also play a crucial role in making a plan for top line growth.

Raw material and other input factors analysis will help to plan effectively for the bottom line.

2. Competitive intelligence

In a competitive marketplace, up-to-date information can make the difference between keeping pace, getting ahead, or being left behind. A smart intelligence operation can serve as an early-warning system for disruptive changes in the competitive landscape, whether that change is a rival's new product or pricing strategy or the entrance of an unexpected player into your market.

We also provide you with information that allows you to anticipate what your competitors are planning next. For example, you might gain information on a new product they are getting ready to launch or new services they will add to the business. Hiring us to handle this information collection saves you time and energy, allowing you to focus on your own business while still gaining the necessary knowledge to keep track of competitors.

3. Identification of prospective customers and their satisfaction level with the current supplier:

We have provided the long list of customers and analysed them critically, based on various parameters such as consumption, market type, sustainable business etc. this will help your organisation to develop relations with the consumers. Also, we have identified the factors in which the others customer will switch to you.

Methodology and sources

We follow the following steps to complete the report:

Desk research

Market size, capacity and production information are based on the following:

The sources of desk research are various, including published magazines, journals, government statistics, industrial statistics, customs statistics, association seminars as well as information from the Internet.

A lot of work goes into compilation and analysis of the obtained information.

Primary research

We carry out extensive telephone interviews across the value chain in order to survey the actual market situation. The interviewees we covered are:

Major producers

Major customers

Key traders

Raw materials suppliers

Industry associations

Bottom-up research

According to telephone interviews, matrix excel is designed to deal with complicated and abundant data that are mainly about capacity, output and consumption. Based on the consumption data for 2016 and future demand data from 2017 to 2022 is forecasted with the method of bottom-up research.

Report generation

Logical analysis and scientific ratiocination will be conducted to generate the report. All the data and findings obtained in the above stages are presented in the report clearly.

In this report, we have provided the detailed analysis of more than 60 companies which produce / supply different types of cosmetic chemicals

1. Executive summary

2. Brief Introduction of cosmetic chemicals industry

2.1. Overview

2.2. Product Identification

2.3. Brief overview of global cosmetic chemicals industry by following categories:

2.3.1. Emollients, film formers and moisturizers

2.3.2. Surfactants

2.3.3. Thickening agents

2.3.4. Colorants and pearlescent pigments

2.3.5. Preservatives

2.3.6. Carriers and Powders

2.3.7. Hair Conditioning Polymers

2.3.8. Hair Setting Resins

2.3.9. Antiperspirants and Deodorants

2.3.10. Sunscreen Chemicals

2.3.11. Antidandruff Agents

2.4. Value chain analysis

2.5. Porter five forces analysis of cosmetic chemicals market

2.6. Burning issues in the market such as regulations

2.7. Market dynamics

2.8. Raw material analysis

2.9. Policy and regulations

3. Global market analysis for thickening & gelling agents used in Cosmetics

3.1. Current market analysis for 2016

3.1.1. Cellulose Ethers

3.1.1.1. Hydroxyethylcellulose (HEC)

3.1.1.2. Carboxymethylcellulose (CMC)

3.1.1.3. Methylcellulose (MC)

3.1.1.4. Hydroxypropylmethylcellulose (HPMC)

3.1.1.5. Hydroxypropylcellulose (HPC)

3.1.2. Natural Gums

3.1.2.1. Xanthan Gum

3.1.2.2. Carrageenan

3.1.2.3. Alginate

3.1.2.4. Guar Gum

3.1.2.5. Others

3.1.3. Others

3.1.3.1. Polyacrylic Acid / Polyacrylates / Carbomer

3.1.3.2. Silica Thickener

3.1.3.3. Ester Ethoxylates (Polyol Esters)

3.1.3.4. Polyacrylamides

3.2. Forecast from 2017 to 2022

3.2.1. Cellulose Ethers

3.2.1.1. Hydroxyethylcellulose (HEC)

3.2.1.2. Carboxymethylcellulose (CMC)

3.2.1.3. Methylcellulose (MC)

3.2.1.4. Hydroxypropylmethylcellulose (HPMC)

3.2.1.5. Hydroxypropylcellulose (HPC)

3.2.2. Natural Gums

3.2.2.1. Xanthan Gum

3.2.2.2. Carrageenan

3.2.2.3. Alginate

3.2.2.4. Guar Gum

3.2.2.5. Others

3.2.3. Others

3.2.3.1. Polyacrylic Acid / Polyacrylates / Carbomer

3.2.3.2. Silica Thickener

3.2.3.3. Ester Ethoxylates (Polyol Esters)

3.2.3.4. Polyacrylamides

3.2.4. Key growth drivers

3.2.5. Key challenges

4. North America market analysis for thickening & gelling agents used in Cosmetics

4.1. Current market analysis for 2016

4.1.1. Cellulose Ethers

4.1.1.1. Hydroxyethylcellulose (HEC)

4.1.1.2. Carboxymethylcellulose (CMC)

4.1.1.3. Methylcellulose (MC)

4.1.1.4. Hydroxypropylmethylcellulose (HPMC)

4.1.1.5. Hydroxypropylcellulose (HPC)

4.1.2. Natural Gums

4.1.2.1. Xanthan Gum

4.1.2.2. Carrageenan

4.1.2.3. Alginate

4.1.2.4. Guar Gum

4.1.2.5. Others

4.1.3. Others

4.1.3.1. Polyacrylic Acid / Polyacrylates / Carbomer

4.1.3.2. Silica Thickener

4.1.3.3. Ester Ethoxylates (Polyol Esters)

4.1.3.4. Polyacrylamides

4.2. Forecast from 2017 to 2022

4.2.1. Cellulose Ethers

4.2.1.1. Hydroxyethylcellulose (HEC)

4.2.1.2. Carboxymethylcellulose (CMC)

4.2.1.3. Methylcellulose (MC)

4.2.1.4. Hydroxypropylmethylcellulose (HPMC)

4.2.1.5. Hydroxypropylcellulose (HPC)

4.2.2. Natural Gums

4.2.2.1. Xanthan Gum

4.2.2.2. Carrageenan

4.2.2.3. Alginate

4.2.2.4. Guar Gum

4.2.2.5. Others

4.2.3. Others

4.2.3.1. Polyacrylic Acid / Polyacrylates / Carbomer

4.2.3.2. Silica Thickener

4.2.3.3. Ester Ethoxylates (Polyol Esters)

4.2.3.4. Polyacrylamides

4.2.4. Key growth drivers

4.2.5. Key challenges

5. Europe market analysis for thickening & gelling agents used in Cosmetics

5.1. Current market analysis for 2015

5.1.1. Cellulose Ethers

5.1.1.1. Hydroxyethylcellulose (HEC)

5.1.1.2. Carboxymethylcellulose (CMC)

5.1.1.3. Methylcellulose (MC)

5.1.1.4. Hydroxypropylmethylcellulose (HPMC)

5.1.1.5. Hydroxypropylcellulose (HPC)

5.1.2. Natural Gums

5.1.2.1. Xanthan Gum

5.1.2.2. Carrageenan

5.1.2.3. Alginate

5.1.2.4. Guar Gum

5.1.2.5. Others

5.1.3. Others

5.1.3.1. Polyacrylic Acid / Polyacrylates / Carbomer

5.1.3.2. Silica Thickener

5.1.3.3. Ester Ethoxylates (Polyol Esters)

5.1.3.4. Polyacrylamides

5.2. Forecast from 2017 to 2022

5.2.1. Cellulose Ethers

5.2.1.1. Hydroxyethylcellulose (HEC)

5.2.1.2. Carboxymethylcellulose (CMC)

5.2.1.3. Methylcellulose (MC)

5.2.1.4. Hydroxypropylmethylcellulose (HPMC)

5.2.1.5. Hydroxypropylcellulose (HPC)

5.2.2. Natural Gums

5.2.2.1. Xanthan Gum

5.2.2.2. Carrageenan

5.2.2.3. Alginate

5.2.2.4. Guar Gum

5.2.2.5. Others

5.2.3. Others

5.2.3.1. Polyacrylic Acid / Polyacrylates / Carbomer

5.2.3.2. Silica Thickener

5.2.3.3. Ester Ethoxylates (Polyol Esters)

5.2.3.4. Polyacrylamides

5.2.4. Key growth drivers

5.2.5. Key challenges

6. China market analysis for thickening & gelling agents used in Cosmetics

6.1. Current market analysis for 2016

6.1.1. Cellulose Ethers

6.1.1.1. Hydroxyethylcellulose (HEC)

6.1.1.2. Carboxymethylcellulose (CMC)

6.1.1.3. Methylcellulose (MC)

6.1.1.4. Hydroxypropylmethylcellulose (HPMC)

6.1.1.5. Hydroxypropylcellulose (HPC)

6.1.2. Natural Gums

6.1.2.1. Xanthan Gum

6.1.2.2. Carrageenan

6.1.2.3. Alginate

6.1.2.4. Guar Gum

6.1.2.5. Others

6.1.3. Others

6.1.3.1. Polyacrylic Acid / Polyacrylates / Carbomer

6.1.3.2. Silica Thickener

6.1.3.3. Ester Ethoxylates (Polyol Esters)

6.1.3.4. Polyacrylamides

6.2. Forecast from 2017 to 2022

6.2.1. Cellulose Ethers

6.2.1.1. Hydroxyethylcellulose (HEC)

6.2.1.2. Carboxymethylcellulose (CMC)

6.2.1.3. Methylcellulose (MC)

6.2.1.4. Hydroxypropylmethylcellulose (HPMC)

6.2.1.5. Hydroxypropylcellulose (HPC)

6.2.2. Natural Gums

6.2.2.1. Xanthan Gum

6.2.2.2. Carrageenan

6.2.2.3. Alginate

6.2.2.4. Guar Gum

6.2.2.5. Others

6.2.3. Others

6.2.3.1. Polyacrylic Acid / Polyacrylates / Carbomer

6.2.3.2. Silica Thickener

6.2.3.3. Ester Ethoxylates (Polyol Esters)

6.2.3.4. Polyacrylamides

6.2.4. Key growth drivers

6.2.5. Key challenges

7. Asia pacific (excluding China) market analysis for thickening & gelling agents used in Cosmetics

7.1. Current market analysis for 2016

7.1.1. Cellulose Ethers

7.1.1.1. Hydroxyethylcellulose (HEC)

7.1.1.2. Carboxymethylcellulose (CMC)

7.1.1.3. Methylcellulose (MC)

7.1.1.4. Hydroxypropylmethylcellulose (HPMC)

7.1.1.5. Hydroxypropylcellulose (HPC)

7.1.2. Natural Gums

7.1.2.1. Xanthan Gum

7.1.2.2. Carrageenan

7.1.2.3. Alginate

7.1.2.4. Guar Gum

7.1.2.5. Others

7.1.3. Others

7.1.3.1. Polyacrylic Acid / Polyacrylates / Carbomer

7.1.3.2. Silica Thickener

7.1.3.3. Ester Ethoxylates (Polyol Esters)

7.1.3.4. Polyacrylamides

7.2. Forecast from 2017 to 2022

7.2.1. Cellulose Ethers

7.2.1.1. Hydroxyethylcellulose (HEC)

7.2.1.2. Carboxymethylcellulose (CMC)

7.2.1.3. Methylcellulose (MC)

7.2.1.4. Hydroxypropylmethylcellulose (HPMC)

7.2.1.5. Hydroxypropylcellulose (HPC)

7.2.2. Natural Gums

7.2.2.1. Xanthan Gum

7.2.2.2. Carrageenan

7.2.2.3. Alginate

7.2.2.4. Guar Gum

7.2.2.5. Others

7.2.3. Others

7.2.3.1. Polyacrylic Acid / Polyacrylates / Carbomer

7.2.3.2. Silica Thickener

7.2.3.3. Ester Ethoxylates (Polyol Esters)

7.2.3.4. Polyacrylamides

7.2.4. Key growth drivers

7.2.5. Key challenges

8. Rest of the world market analysis for thickening & gelling agents used in Cosmetics

8.1. Current market analysis for 2016

8.1.1. Cellulose Ethers

8.1.1.1. Hydroxyethylcellulose (HEC)

8.1.1.2. Carboxymethylcellulose (CMC)

8.1.1.3. Methylcellulose (MC)

8.1.1.4. Hydroxypropylmethylcellulose (HPMC)

8.1.1.5. Hydroxypropylcellulose (HPC)

8.1.2. Natural Gums

8.1.2.1. Xanthan Gum

8.1.2.2. Carrageenan

8.1.2.3. Alginate

8.1.2.4. Guar Gum

8.1.2.5. Others

8.1.3. Others

8.1.3.1. Polyacrylic Acid / Polyacrylates / Carbomer

8.1.3.2. Silica Thickener

8.1.3.3. Ester Ethoxylates (Polyol Esters)

8.1.3.4. Polyacrylamides

8.2. Forecast from 2017 to 2022

8.2.1. Cellulose Ethers

8.2.1.1. Hydroxyethylcellulose (HEC)

8.2.1.2. Carboxymethylcellulose (CMC)

8.2.1.3. Methylcellulose (MC)

8.2.1.4. Hydroxypropylmethylcellulose (HPMC)

8.2.1.5. Hydroxypropylcellulose (HPC)

8.2.2. Natural Gums

8.2.2.1. Xanthan Gum

8.2.2.2. Carrageenan

8.2.2.3. Alginate

8.2.2.4. Guar Gum

8.2.2.5. Others

8.2.3. Others

8.2.3.1. Polyacrylic Acid / Polyacrylates / Carbomer

8.2.3.2. Silica Thickener

8.2.3.3. Ester Ethoxylates (Polyol Esters)

8.2.3.4. Polyacrylamides

8.2.4. Key growth drivers

8.2.5. Key challenges

9. Historical & forecast price analysis for the following regions

9.1. North America

9.2. Western Europe

9.3. Asia pacific excluding China

9.4. China

10. Analysis of key manufacturers of thickening & gelling agents used in Cosmetics *

10.1. Company 1

10.1.1. Company introduction

10.1.2. SWOT analysis in terms of thickening & gelling agents used in Cosmetics

10.1.3. Financials*

10.1.4. Employee

10.1.5. R&D details**

10.1.6. Products offerings

10.1.6.1. Thickening & gelling agents used in Cosmetics

10.1.6.2. Other products

10.1.7. Plant locations

10.1.7.1. Details of thickening & gelling agents used in Cosmetics plant

10.1.8. Installed capacity of thickening & gelling agents used in Cosmetics

10.1.8.1. Capacity expansion plans

10.1.8.2. Capacity shares of thickening & gelling agents used in Cosmetics

10.1.9. Strategic imperatives

10.2. Same parameters as above will be repeated for the following companies across:

10.2.1. North America

10.2.1.1. Ashland Aqualon Functional Ingredients

10.2.1.2. Dow Chemical

10.2.1.3. CP Kelco

10.2.1.4. Rhodia

10.2.1.5. Rantec Corporation

10.2.1.6. Archer Daniels Midland

10.2.1.7. Pfizer

10.2.1.8. Evonik

10.2.1.9. Cabot Corporation

10.2.1.10. Elementis

10.2.1.11. Lubrizol

10.2.1.12. SEPPIC

10.2.2. Western Europe

10.2.2.1. Amberger Kaolinwerke GmbH

10.2.2.2. Akzo Nobel

10.2.2.3. Ashland

10.2.2.4. BASF

10.2.2.5. Cabot Carbon

10.2.2.6. Cesalpinia Chemicals SpA

10.2.2.7. Clariant AG

10.2.2.8. Cognis GmbH

10.2.2.9. CP Kelco

10.2.2.10. Danisco

10.2.2.11. Dow Wolff Cellulosics

10.2.2.12. Evonik

10.2.2.13. FMC BioPolymer

10.2.2.14. Grace GmbH

10.2.2.15. Huber

10.2.2.16. INEOS Silica

10.2.2.17. ISP Alginates Limited

10.2.2.18. Jungbunzlauer

10.2.2.19. Lubrizol

10.2.2.20. Rhodia

10.2.2.21. Roquette Frères SA

10.2.2.22. SEPPIC

10.2.2.23. SE Tylose GmbH

10.2.2.24. 3V Sigma SpA

10.2.2.25. Vevy Europe

10.2.2.26. Wacker Chemie AG

10.2.3. Asia Pacific

10.2.3.1. Carrageenan Chuo Food Materials Company Limited

10.2.3.2. Daicel Chemical Industries Limited

10.2.3.3. Dai-ichi Kogyo Seiyaku Company Limited

10.2.3.4. Dainihon Kasei

10.2.3.5. Danisco

10.2.3.6. DSP Gokyo Food & Chemicals Company Limited

10.2.3.7. Fuji Chemical Industry Company Limited

10.2.3.8. Ina Food Industry Company Limited

10.2.3.9. Kimika Corporation

10.2.3.10. Lubrizol

10.2.3.11. Matsumoto Yushi-Seiyaku Company Limited

10.2.3.12. MRC Polysaccharide Company Limited

10.2.3.13. Nihon Junyaku Company Limited

10.2.3.14. Nippon Carrageenan Industry Corp.

10.2.3.15. Osaka Organic Chemicals Company Limited

10.2.3.16. Rhodia

10.2.3.17. SEPPIC

10.2.3.18. Shin-Etsu Chemical Company, Limited

10.2.3.19. Sumitomo Seika Chemicals Company Limited

10.2.3.20. The Synthetic Chemical Industry Company Limited

10.2.3.21. Toho Chemical Industry Company Limited

10.2.3.22. Tosoh Silica Corporation

10.2.3.23. Wako Pure Chemical Industries

11. Conclusion

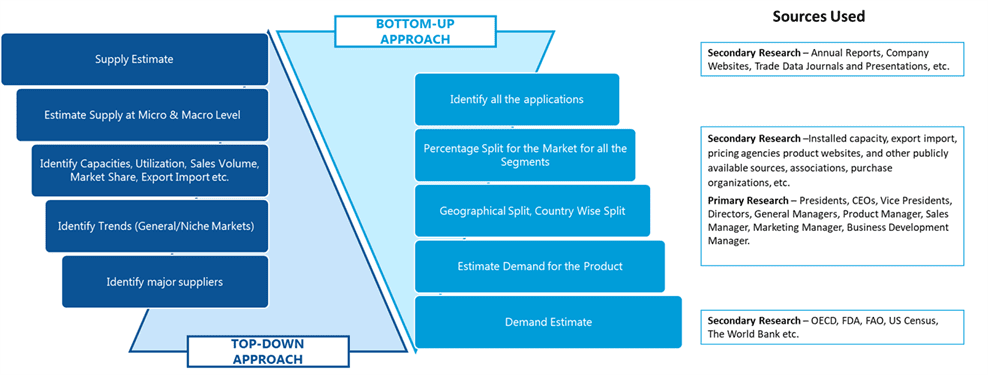

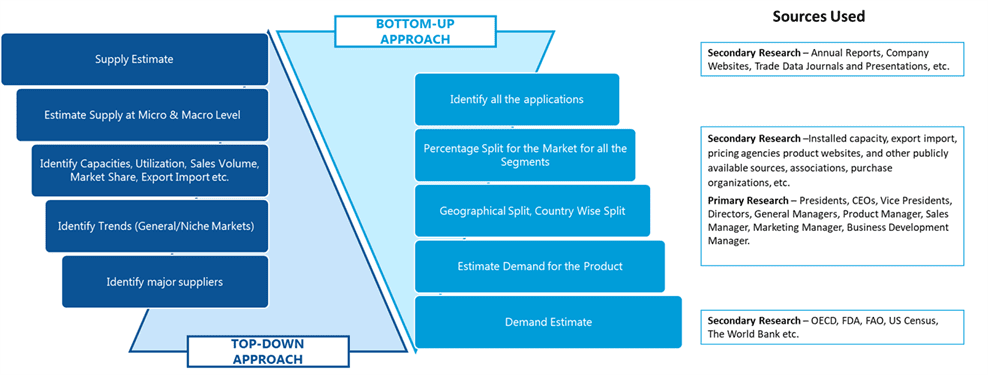

SDMR employs a three way data triangulation approach to arrive at market estimates. We use primary research, secondary research and data triangulation by top down and bottom up approach

Secondary Research:

Our research methodology involves in-depth desk research using various secondary sources. Data is gathered from association/government publications/databases, company websites, press releases, annual reports/presentations/sec filings, technical papers, journals, research papers, magazines, conferences, tradeshows, and blogs.

Key Data Points through secondary research-

Macro-economic data points

Import Export data

Identification of major market trends across various applications

Primary understanding of the industry for both the regions

Competitors analysis for the production capacities, key production sites, competitive landscape

Key customers

Production Capacity

Pricing Scenario

Cost Margin Analysis

Key Data Points through primary research-

Major factors driving the market and its end application markets

Comparative analysis and customer analysis

Regional presence

Collaborations or tie-ups

Annual Production, and sales

Profit Margins

Average Selling Price

Data Triangulation:

Data triangulation is done using top down and bottom approaches. However, to develop accurate market sizing estimations, both the methodologies are used to accurately arrive at the market size. Insert Image